View of chassis, almost bare!

Bare chassis being cleaned prior to examination and needle blasting:

Air powered needle gun checking for weak and corroded metal:

Underside of chassis – showing excellent front, T shirt with holes, plating on outriggers, patched on rear:

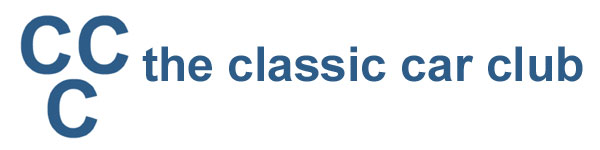

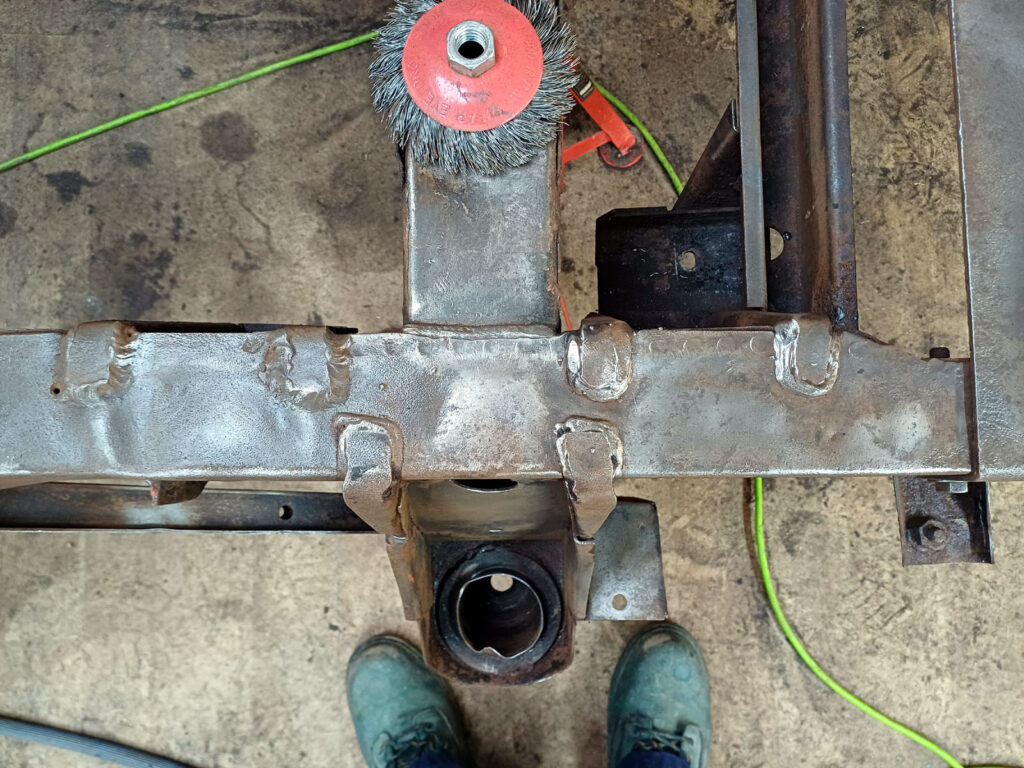

Chassis after some needling and wire brushing:

Chassis after wire brushing and treating with air powered needle gun to expose any holes:

Underside of chassis with T shirt removed showing surface rust:

Chassis outrigger on passenger side – the patches were opened to see what was inside. Although plenty of rust the internals were sound. However it is being replaced:

Before removal of the outriggers we need to create a jig so that the replacements can be fitted correctly:

When the outriggers were removed part of the chassis showed pin holes so needed to be replaced. First image shows the corrosion on top and side of chassis where outrigger attaches. Next shows internal view – looks like mice used the chassis as a pantry for nuts!

Comparision of 2 types of outriggers – first one we bought didn’t fit the chassis correctly so we bought the BMH version which uses original triumph tooling. The BMH version seems more substantial with more structural support.

One outrigger in – photos show diff strengthener plates; alignment of outrigger using jig; BMH label; outrigger 90% fitted; removal of outrigger from the other side.

Original patch replaced with new metal let into the chassis:

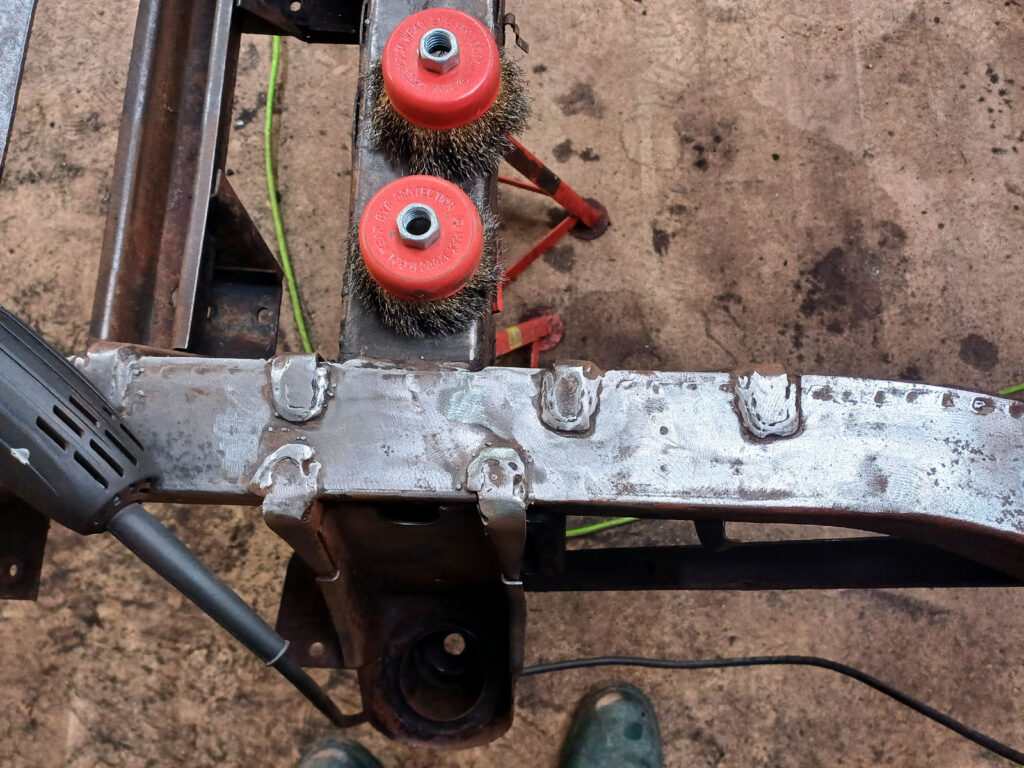

Both outriggers fitted, and new T shirt plate welded. Ready to be turned over and top T shirt fitted. Note comparison with old T shirt:

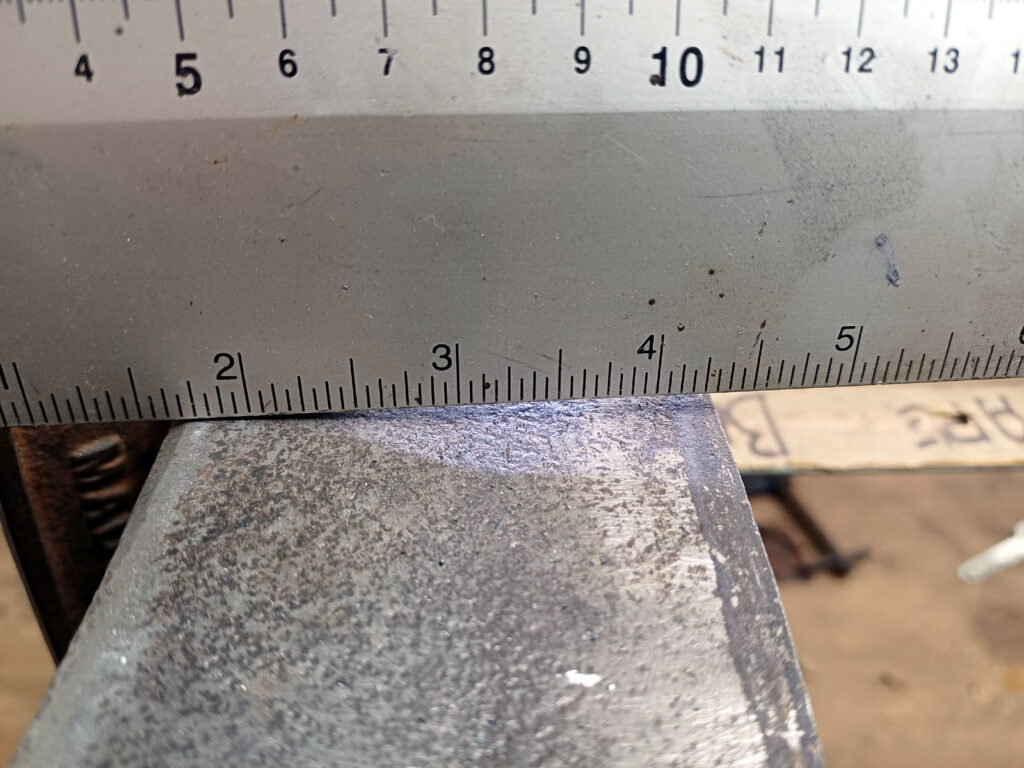

Straight edge to show difference between inner chassis leg and outer chassis leg, which is approx 1/4″ top and bottom:

Chassis turned over. We used a straight edge to check the top of the chassis, as we did above for the underneath of the chassis. Also the bottom T shirt is welded on the inside.

Top part of chassis now painted!

Three people painting the chassis takes no time at all!

Bottom of chassis now painted, with 10mm holes in outriggers and other areas for waxoyl injection: